Air Filtration Maintenance

Onsite Preventative Maintenance

Onsite service is a complete program offered to clients within New England. The collection cells are not just cleaned at every service interval, but tested & repaired, ensuring proper function and clean air!

How it Works

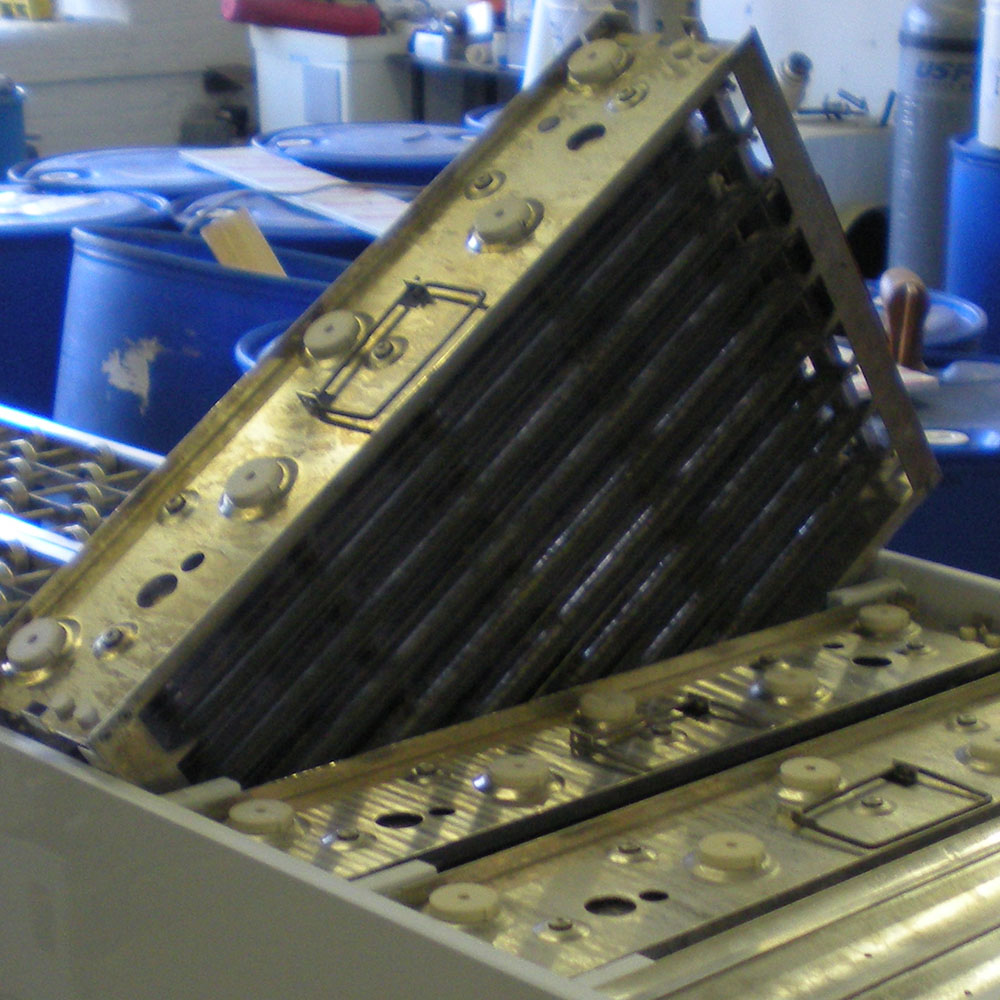

We Deliver Clean Cells to Your Facility

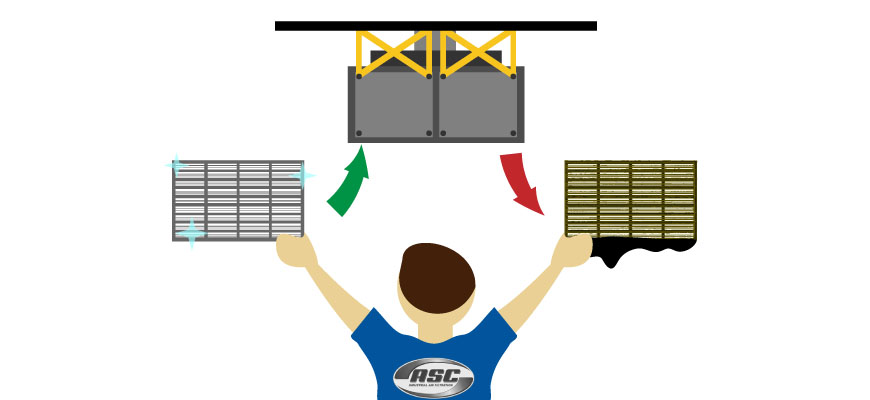

We Replace the Dirty Cells for You

We Take Your Dirty Cells Back

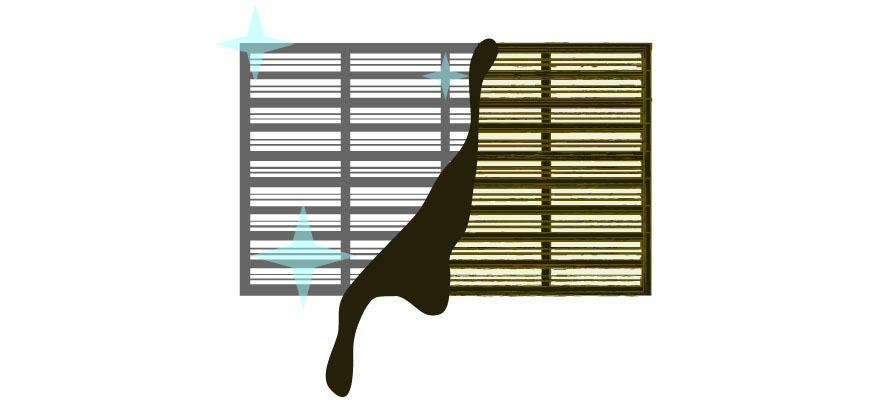

Dirty Cells are Cleaned, Process Repeats

No Time? No Problem! Let ASC do the Dirty Work!

Step 1

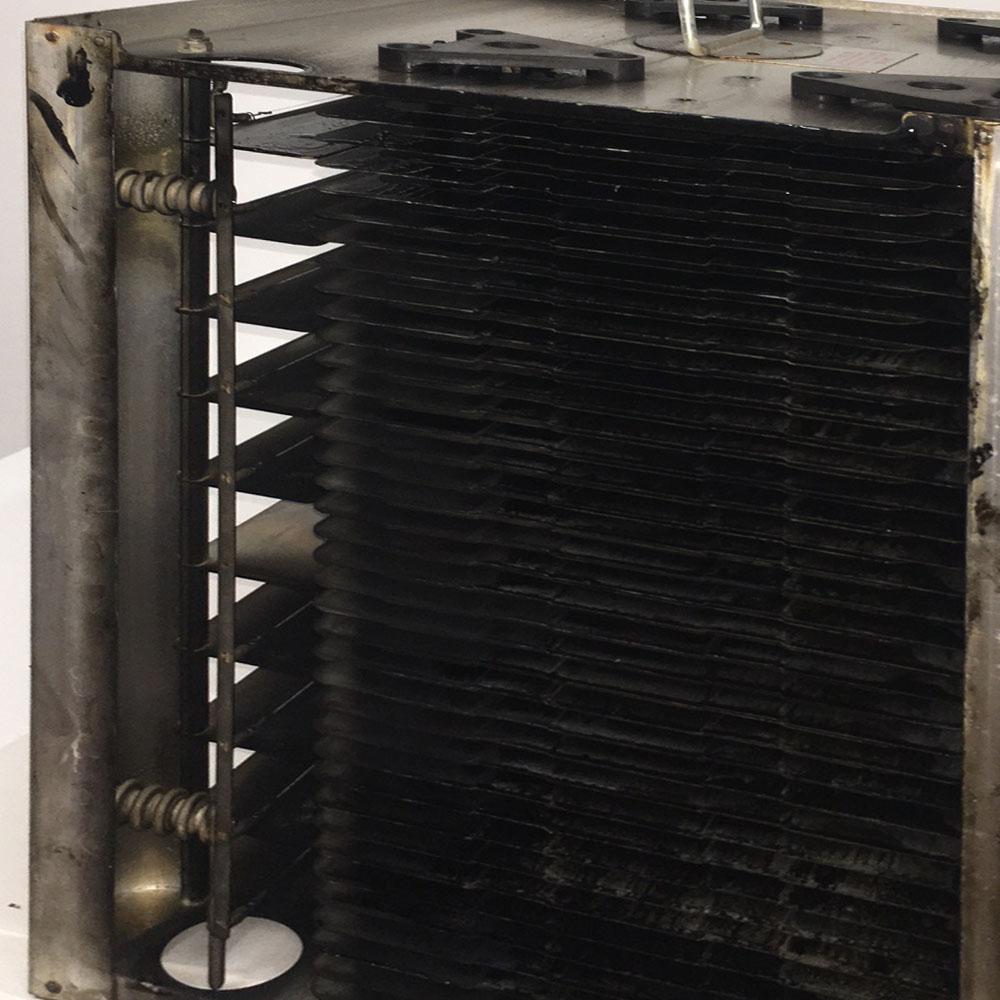

We bring the electrostatic collection cells & mesh filters to your facility in a leak free plastic crate or container. Each cell is tested after each cleaning ensuring that proper voltage is carried through the ionizer and collection plate sections of the unicell.

Step 2

Our experienced professionals remove the dirty collection cells & mesh filters and replace them with the clean ones.

Step 3

We pack up the dirty collection cells & mesh filters and take them back with us to be cleaned at our facilities.

Step 4

Start Small. Do you have a large quantity of units? If you’re hesitant, let’s start servicing a few, if you like the service program, you can expand. Broken ionizer wires! Repair of broken wires are included in the service. We recycle all waste material.

Curious to See How It's Done?

New Onsite Service Clients

ASC Technicians Will do the Following:

Identify all the air filtration equipment in the factory and tag it with a number.

Test the efficiency of existing equipment with a particle counter, and identify any problems, then make any repairs once authorized.

Easily break up and remove long and twisted chips

After Consultation

ASC Technicians Will do the Following:

Exchange the contaminated collection cells with cleaned ones on a pre-determined routine basis.

Clean the interior and exterior of the machines, and ensure that they are working properly by testing voltages to the Ionizer and collection cell assemblies.

Remove from the factory the contaminated filters which are then cleaned and tested at our facility for re-use.

There is often little or no machine down time with routine cleaning.

ASC Technicians

Professional & Quality Craftsmanship

Are guided by set of wash & test procedures insuring consistently clean & functioning collection cells at time of delivery.

Are routinely trained to quickly trouble shoot the various problems that arise with the various models of electrostatic mist collectors.

Carry most replacement parts on our trucks so that problems can quickly be solved without an additional visit.

Are routinely trained and tested with Lock Out – Tag Out [LOTO] procedures & are certified to use powered truck equipment on the factory floor [where applicable]

Are fully ensured.

Low or No Start up Costs

-

Cell Replacement Kits are Delivered

- Lower or possibly no start-up costs depending on the condition of your equipment.

- No ongoing repair costs of collection cells as they are examined and repaired at each service interval.

-

Integrated Preventative Maintenance

- Each machine is identified (Make, model, year, vin#, voltage) preventing the re-purchase of faulty parts that should still be covered under the original warranty.

- The service records for each machine are kept on hand and emailed after each service. This can provide detailed information in the event of OSHA or EPA litigation.

- Email reminders of the upcoming service dates.